How to Select the Right Planetary Gearbox for Your Motor: Tips for Optimal Performance

There are many factors affect the selection of gearboxes in a given application, including torque, radial load on the output shaft, input and output speed, backlash, noise, mounting arrangement and operating conditions. The consideration and steps involved are as follows.

Nominal output torque is the most important indicator, exceeding the nominal output torque will reduce the service life or precision of the gearbox, or even cause damage to internal components. The planetary gearboxes are often sized on the basis of the torque parameter listed in the specifications. Therefore, it is necessary to select the appropriate gearbox size based on the torque applied to the output shaft.

〈READ MORE: How to Avoid The Running Noise of Gearboxes? 〉

〈READ MORE: Advantages and Applications of Planetary Gearboxes〉

Torque

The torque of a planetary gearbox includes nominal output torque, maximum torque and emergency stop torque.Nominal torque

Typically referring to the load that the planetary gearbox can operate for 20,000 hours at the nominal input speed without damage.Maximum torque

Also known as peak torque or acceleration torque, refers to the maximum torque that the planetary gearbox can transmit power in moment. If this torque is exceeded, it may cause damage to the planetary gearbox or affect the service life.Emergency stop torque

Refers to the design torque limit of the gearbox, generally it is 3 times the nominal output torque.Nominal output torque is the most important indicator, exceeding the nominal output torque will reduce the service life or precision of the gearbox, or even cause damage to internal components. The planetary gearboxes are often sized on the basis of the torque parameter listed in the specifications. Therefore, it is necessary to select the appropriate gearbox size based on the torque applied to the output shaft.

Radial and Axial Loads

Radial and axial loads refer to the maximum force applied to the output shaft in the radial and axial directions. These loads come from the transmission components mounted on the output shaft, such as chain sprocket, pulley, timing belts, gears, and other transmission elements. Radial and axial loads are related to the strength and rigidity of the gearbox's output shaft, bearings, gears, and gearboxes. Overload may cause damage to the gearbox and its parts.Precision Levels

The precision of a planetary gearbox is often expressed in terms of backlash, which is one of the main indicators of a planetary gearbox. Backlash is mainly due to the gap between the teeth when the gears mesh, which results in the rotation output of the gearbox to be insufficient. The precision level is related to the price of a planetary gearbox, and the choice of precision level depends on your specific application. High-performance and accurate positioning applications require high-precision level (low backlash) gearboxes. For applications that focus on torque or do not require high precision, more cost-effective models can be considered.Noise

The noise of gearbox is related to gear material, machining accuracy, contact ratio between meshing gears, backlash, tooth shape, smoothness of tooth surface, and operating conditions. Generally, gears with higher precision produce less noise during operation, and helical gears are often quieter than spur gears. Users can choose the most suitable product based on their actual needs.〈READ MORE: How to Avoid The Running Noise of Gearboxes? 〉

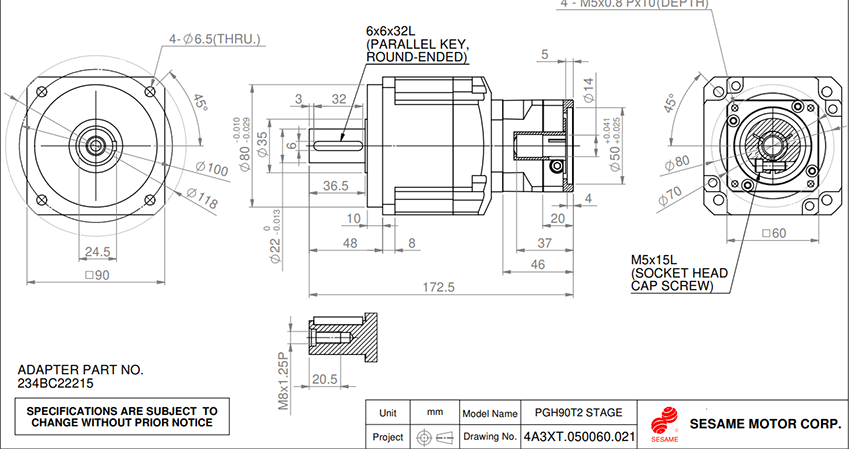

Gearbox Configuration

Planetary gearboxes can be mainly divided into parallel output shaft (in-line) type and right-angle type. In-line type is more commonly used, but when the installation space is limited, the right-angle type can be selected. Both in-line and right-angle gearboxes can be selected with either shaft output or flange output. Both outputs can be fitted with general transmission components such as gears, pulleys, and sprockets. Generally, shaft output can meet most transmission needs. However, when the application requires special large axial or radial forces, flange output can be selected to provide higher load capacity.Other Considerations

Although planetary gearboxes are mainly used in the field of automation, the applications have been increasing in many harsh working conditions such as extremely high or low temperatures, corrosive environments, high dust and high IP requirements because of their high performance in torque density, rigidity, precision and efficiency. In such cases, special consideration must be given to material, protection level, surface treatment, sealing elements, lubrication and component dimensions in order to maintain its performance and lifespan under various operating conditions.〈READ MORE: Advantages and Applications of Planetary Gearboxes〉