- HOME

- Blog

- In-depth Learning

- What Are Torque Motors and How They Work?

What Are Torque Motors and How They Work?

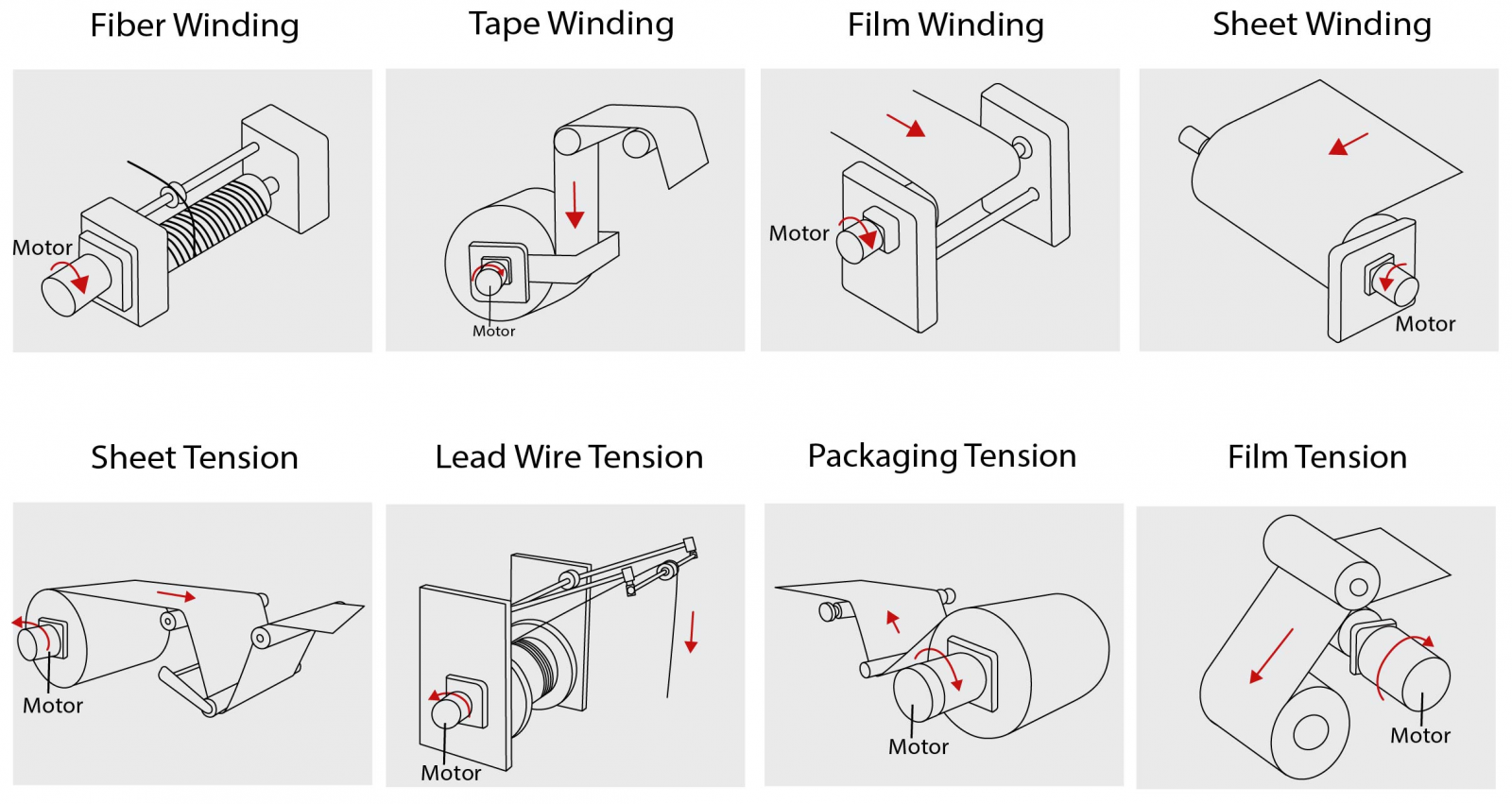

Torque motors are often used for tension control in the manufacturing process, which is a relatively rare but important motor application. Tension control refers to the control of continuous lengths of sheet or film materials, cables or wires during manufacturing. It is necessary to maintain a certain tension on the product to manage and keep material thickness or elongation as constant as possible. For example, the winding or unwinding control of paper rolls, tapes, plastic films, wires or webbing. Tension control also keeps the product aligned and helps to prevent defects such as wrinkles or breaks.

.png)

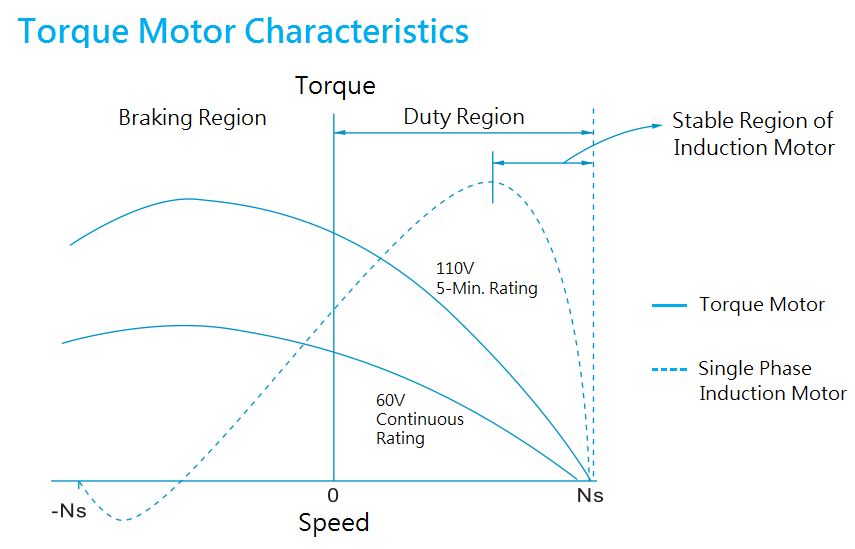

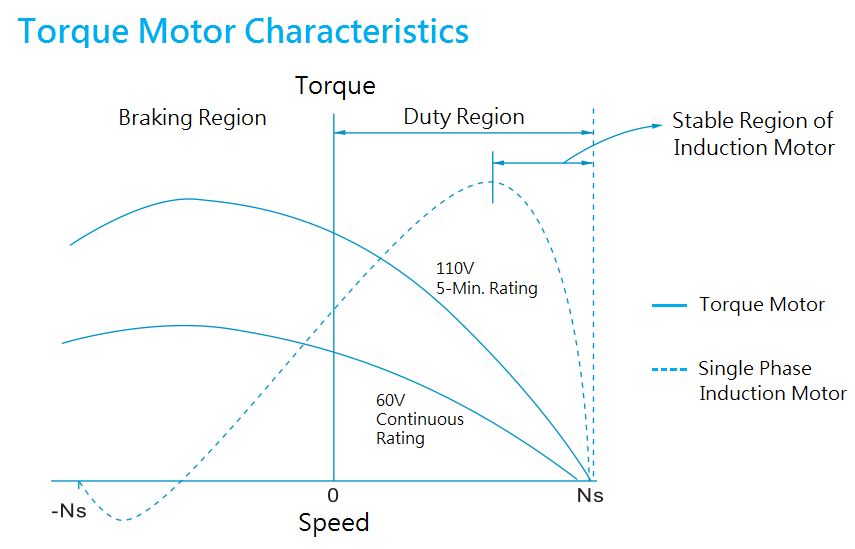

The voltage supplied to the torque motor and the load on the motor determine the output torque and speed of the motor. By changing the voltage supply, the expected output torque is obtained and rotation speed is also changed based on the unique sloping performance characteristic of torque motor.

Comparision of Torque Motors and General Induction Motors

In practice, servo motors are often used for tension control applications. But if simply winding or unwinding operations are required instead of precise positioning and dynamic motion control, the torque motors are cost-effective alternatives. Sesame Motor provides high-quality torque motors equipped with thermal protection switches and cooling fans (40W output models) for such special applications, so that the motors can function under stable and continuous operation for long time. In addition, speed reducers are available for torque motors to increase output torque just like gear motors and have a wider range of applications.

Contact Sesame Motor for more specifications and information about torque motors.

What are Torque Motors?

Torque motor is a special designed asynchronous motor. Its operating principle is the same as induction motor, but the required speed and mechanical properties are obtained by increasing the rotor resistance. Compared with the same rank induction motor, the torque motor has a larger stall torque and the characteristic of stable operation at low speeds, so it is suitable for tension control applications of high loading and low speeds, or for operations in which a stop position is reached after a short-time running and has to be maintained safely. They are designed to be able to control their torque and can be stalled (the motor speed is zero) continuously without overheating, which are significant characteristics of the motors that are used in tension control..png)

The voltage supplied to the torque motor and the load on the motor determine the output torque and speed of the motor. By changing the voltage supply, the expected output torque is obtained and rotation speed is also changed based on the unique sloping performance characteristic of torque motor.

Differences Between Torque Motors and Induction Motors

The torque motor is specially designed to provide output torque at a low speed, or to maintain the torque at zero speed after a short period of operation. They are significantly different from general induction motors in application. A standard induction motor tries to maintain the speed as it is loaded while a torque motor will drop in speed as it is loaded without burning out due to overheat.Comparision of Torque Motors and General Induction Motors

| Torque Motors | General Induction Motors | |

| Operation | Low voltage and speed when loaded | Constant voltage and speed when loaded |

| Starting Torque | High | Low |

| Rated Speed | Low | High |

| Speed Adjust | By voltage regulator | Variable speed motors or VFD |

Types of SESAME Torque Motor

There are two types of SESAME torque motor available - standard type and built-in voltage regulator type.Standard Type Torque Motor

An external device is required to change the input voltage of the motor, such as a power controller to adjust the motor speed and torque.

Built-In Voltage Regulator Type

The internal voltage regulator has been built in the terminal box of the motor, which can control the input voltage according to the affiliated variable resistor to adjust the motor speed.How and Where Are Torque Motors Used?

Some applications require the motor to be able to control its torque, such as coiling operations, winding or unwinding, maintaining tension or holding a tool or equipment in position after pushing it to a specific position. In the coiling operation, no matter whether the motor is on the coiling side or the coiled side, maintaining proper tension can prevent the coiled material from slack or loose.Winding

Winding is a very important working procedure in the processing of textile, wire and cable, metal sheet processing and paper making. During material or product winding, the diameter of the reel gradually increases, but the winding tension must remain constant. In order to keep the tension constant during the winding operation, the output torque of the motor driving the reel must be increased while the reel diameter increases, but the motor rotation speed must be decreased accordingly to keep the winding speed. Too much tension will result in the wire diameter or material thickness may be too thin or even broken. Insufficient tension may cause uneven product thickness or loose winding. The special mechanical characteristics of torque motors are just right for such type of winding and tension control applications. For example, the winding or coiling operation of textile fiber, cloth, webbing, tape, film, plastic or rubber sheet, etc.Unwinding

When the product or material that has been wound needs to be pulled out and conveyed to the next processing procedure, the torque motor can be used to maintain constant tension on the roll or reel opposite to the conveying direction, and change the rotation speed with the diameter changes of the reel or disc. For example, a full roll of labels or stickers are maintained under tension in printing or packaging equipment. The torque motor is installed on the unwinding side, and its rotation direction is opposite to that of the winding motor. The torque motor is used to offer braking function and keeps proper tension.

Stall Torque

In some applications, the motor is required to provide output torque when the rotation speed is zero after running for a period of time (the so-called rotor blocked, where there is AC power input but the motor does not rotate). For example, holding down objects, setting switches or the initial and final stages of cable winding, when the motor must maintain tension and output torque at zero speed. Due to the high impedance of the torque motor, the motor winding temperature stays within its thermal limits without burning up when the motor is stalled.

Conclusion

In practice, servo motors are often used for tension control applications. But if simply winding or unwinding operations are required instead of precise positioning and dynamic motion control, the torque motors are cost-effective alternatives. Sesame Motor provides high-quality torque motors equipped with thermal protection switches and cooling fans (40W output models) for such special applications, so that the motors can function under stable and continuous operation for long time. In addition, speed reducers are available for torque motors to increase output torque just like gear motors and have a wider range of applications.Contact Sesame Motor for more specifications and information about torque motors.