- HOME

- FAQ

- Planetary Gearboxes

- What is backlash? Why can't it be zero?

What is backlash? Why can't it be zero?

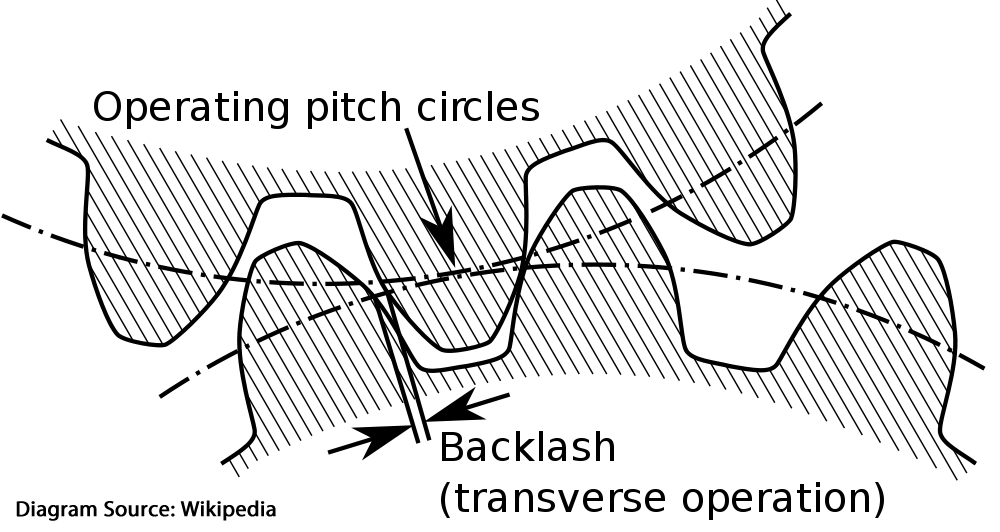

Backlash, sometimes called lost motion or play, is the gap or clearance between two workpieces when they are combined. Here it refers to a clearance between meshed gear teeth. Gear backlash is required to keep gears meshing without getting stuck and to provide enough space for lubricating and thermo expansion. Backlash is reserved to prevent overheating and teeth damage, and to ensure the smooth operation of a gear set or gearboxes. The existence of backlash is also helpful to the assembly and maintenance of a gear set or gearbox, to prolong the service life. Besides, this gap is essential to absorb the gear machining error and the gear deformation under loading.

In practice, when a gearbox or a speed reducer reciprocates back and forth, the backlash effect will accumulate with the increase of the running distance. Such mechanical play causes significant lost motion between speed reducer input and output shafts, making it difficult to achieve accurate positioning in some applications such as precision inspection instruments, machine tools, robotics and other equipment. For these applications that require special accuracy, it is necessary to increase the precision in gear design, machining and assembly, or to use special types of non-traditional gear drive speed reducers. This speed reducer unit can achieve very low or zero backlash and is suitable for applications where performance outweighs cost.

Backlash is commonly measured in arc minute (arcmin) or arc second (arcsec). 1 arc minute = 1/60 of one degree = 0.0167 degree. Taking the planetary gearbox as an example, the backlash can be divided into ≦1arcmin, ≦3 arcmin, ≦5 arcmin, ≦7 arcmin. There is no international standard to follow for the test method for a gearbox or a speed reducer backlash. Backlash is one of the important index data to measure the performance of gearboxes or speed reducers. The smaller the backlash, the higher the precision and the higher the relative price. Therefore, controlling and reducing the backlash of the gearbox or speed reducer is a serious issue of the manufacturers.

To summarize, backlash is the gap between the teeth of the gears in the gearbox. The impact of backlash is actually limited , and it can be compensated in other ways. For applications requiring the highest positioning control accuracy, such as multi-axis robotics, a harmonic speed reducer is recommended. If a little backlash is acceptable on the application, a planetary gearbox can be used. Of course, higher accuracy costs more. In fact, the planetary gearbox with excellent performance has been able to reduce the backlash to less than 1 arc minute. This is the requirement for precision instruments, robotics or machine tools. Moreover, the planetary gearbox has the characteristics of high torsional rigidity, high reduction ratio and compact design, and has infinite potential uses in industrial applications.