Planetary Gearboxes: Types and Pick Up the One Fits You

Speed reducer (gearbox) is an indispensable component in the field of mechanical transmission. In particular, planetary speed reducers (planetary gearboxes) with compact structure, high efficiency and large torque are widely favored by the industrial applications. From automation equipment, industrial machinery to wind power generation, planetary gearboxes can provide stable and high-efficiency transmission. This article will introduce the basic structure, working principle, application advantages and how to choose a suitable planetary gearbox.

〈READ MORE: What Are Planetary Gearboxes?〉

〈READ MORE: Advantages and Applications of Planetary Gearboxes〉

What is a planetary gearbox?

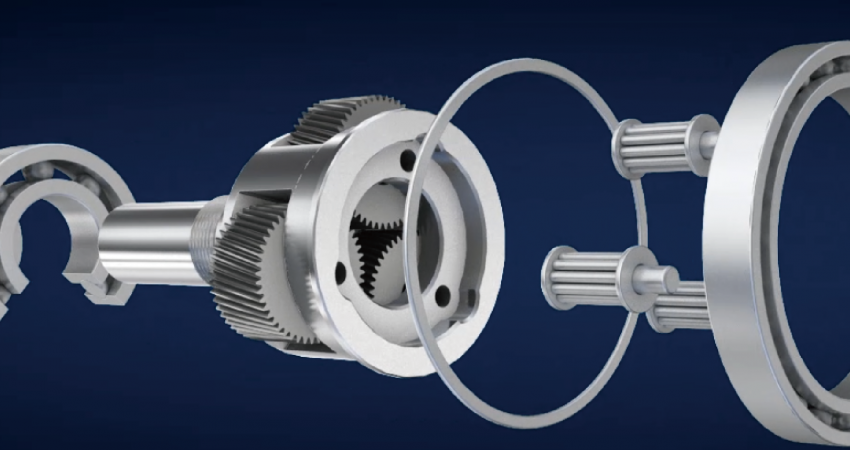

Planetary gearbox is a transmission device composed of sun gear, planet gears, planet carrier and internal ring gear. This type of speed reducer uses the rotation of the planetary gear around the sun gear to achieve deceleration and effectively transmits torque to the applied equipment or machinery. Due to the characteristics of the planetary gear train, the planetary gearbox has high torque density and good vibration resistance, so it is particularly suitable for high-load industrial applications.〈READ MORE: What Are Planetary Gearboxes?〉

Advantages of planetary gearbox

Planetary gearboxes have many unique advantages that make them useful in a variety of applications:High efficiency

The multi-tooth contact design of the planetary gearbox reduces energy loss and the transmission efficiency can reach more than 90%. This allows it to effectively reduce energy consumption during long-term operation.High precision

The best precision of the planetary gearbox can reach one arc minute or less.High reduction ratio

Planetary gearbox is a multiple-stages combination, so it can be assembled with various different and higher reduction ratios.Large torque output

The multi-tooth contact mechanism of the planetary gearbox allows it to withstand higher loads. It's a great advantages to those equipment that requires high torque output, such as AGVs, AMRs or industrial robotic arms.Compact structure and small size

The planetary gearbox can provide high performance in a small size due to the unique design of its planetary gear set. This is especially important for some applications with limited space, such as robotic arms and precision instruments.Smooth operation and low noise

Multi-tooth contact reduces vibration and noise during power transmission, which makes the planetary gearbox relatively quiet during operation and is very suitable for noise-sensitive applications.〈READ MORE: Advantages and Applications of Planetary Gearboxes〉

Applications of planetary gearboxes

The excellent performance of planetary gearbox makes it widely used in different areas. The following are several main application areas.Industrial machinery

Planetary gearboxes can provide stable and powerful output to ensure that mechanical equipment can maintain efficiency and accuracy during high-load operations. Therefore, planetary gearboxes are widely used in high-load industrial machinery such as robotic arms, conveyor systems, and automated production lines. Due to the durability and high performance, planetary gearboxes can effectively increase production speed and extend the service life of equipment.Precision instruments

Planetary gearbox play an important role in surgical instruments and high-precision diagnostic equipment. Because the planetary gearbox can ensure the accuracy of transmission, thereby improving the precision of operation, and due to the high demand for stability of precision instruments, the planetary gearbox has become an indispensable part of these equipment.Wind power

In order to maintain stable power output under different wind speeds, wind turbines need to maintain stable power output at all times. At this time, planetary gearboxes with high torque and high stability are very suitable for blade transmission in wind power generation system. Planetary gearboxes can effectively optimize the power generation efficiency of wind power generation and ensure that the generator can achieve stable output in long-term operation.Transportation equipment

The planetary gearbox can provide stable power output and precise speed control, and is suitable for driving needs of different loads. The precise control of the planetary gearbox allows the electric vehicle to remain stable during driving, and it can still provide reliable power support even when the heavy vehicle is loaded. These characteristics make planetary gearboxes the ideal choice in drive systems for electric and heavy-duty vehicles.What types are there of planetary gearboxes?

After years of development, there are currently the following types of planetary gearboxes:- Output shaft type, variants are available with a key shaft, smooth shaft and spline shaft, on which belt pulleys, gears and sprockets etc. can be installed.

- The flange type, designed according to ISO9409 specification can be combined with various pinions and pulleys that meet this specification. It is often used in gears and racks because of high torque output features.

- Right angle type, the mounting of servo motor is rotated 90 °, which saves space and makes the overall design of the equipment more compact.

- Custom models available. Sesame has strong and flexible manufacturing capacity, which means that even the products that are not in the catalog can be produced according to the customer's requirement.

Select the planetary gearbox as required

There are many types of planetary gearboxes, and each has its own application. It is not difficult to buy a good product, but rather a suitable one. The following steps should be helpful for you to find a suitable product.- Models: According to the use conditions, the first preliminary positioning of the products is required.

- Size: The frame number is the size of the gearbox that specifically addresses the requirements of the application. Compare the catalog according to the designer's calculation to determine the appropriate frame number.

- Gear Ratio: The ratio corresponds to the speed and torque required by the application and depends on how the designer optimizes these two conditions.

- Backlash: Backlash is the most important indicator of planetary gearboxes and the main reason most designers choose planets. The lowest backlash may not be the best choice. The required torsional backlash must be assessed based on the components used in the application.

- Other Factors: Conditions not listed in standard products such as noise requirements, low temperatures, food and medical applications, corrosion resistance, special dimensions, extra high rigidity etc.