- HOME

- Blog

- Cases Study & Applications

- Gear Motor Applications: Key Industries and Advantages

Gear Motor Applications: Key Industries and Advantages

In the pulse of modern industry, gear motors play a crucial role in power transmission. They drive conveyor belts on automated production lines, material handling systems in logistics, and are widely used in the food, medical, automotive, and aerospace sectors. This article provides an in-depth understanding of gear motors, their advantages, key application industries, and selection tips to help you find the most suitable solution.

〈READ MORE:Choosing Motor Basics: Types of AC Motors & DC Motors〉

〈READ MORE:Motor Power, The Key to Choosing the Right Motor!〉

〈READ MORE:What are Planetary Gearboxes?〉

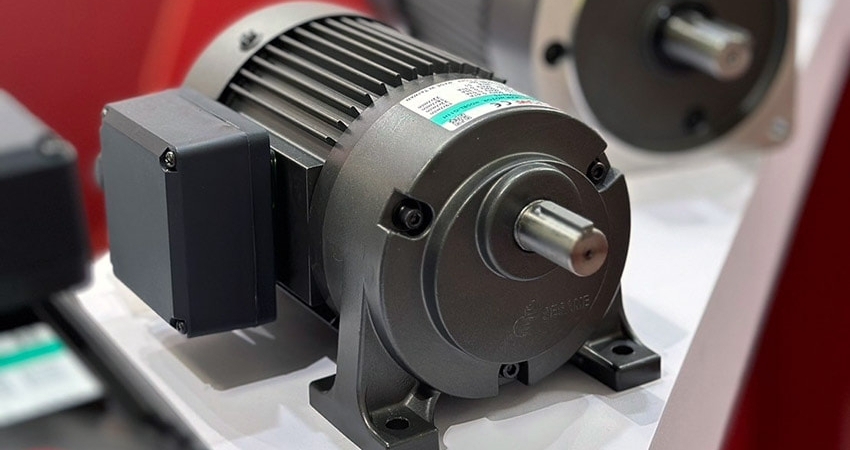

What Is a Gear Motor? The Heart of Industrial Power Transmission

A gear motor is an electromechanical device that combines a motor with a reduction gearbox (also called a speed reducer). The motor provides power, while the gearbox reduces speed and amplifies torque, driving various industrial equipment. The mechanism relies on meshing gears of different sizes to decrease motor speed and increase output torque, enabling small motors to handle high-load conditions. With this design, gear motors balance efficiency, precision, and durability, earning the reputation as the “heart of industrial power.”〈READ MORE:Choosing Motor Basics: Types of AC Motors & DC Motors〉

Why Gear Motors Matter: 3 Key Performance Advantages

The value of a gear motor extends beyond speed reduction. It offers significant benefits in torque output, speed control, and equipment lifespan. Here are three key advantages:1. Significantly Increased Output Torque

The gearbox amplifies the motor's torque by tens or even hundreds of times, allowing small motors to drive heavy loads. Even in confined spaces or limited energy environments, equipment maintains strong driving force. Applications like heavy-duty conveyors, automated storage systems, and mixers rely on gear motors for essential power support.〈READ MORE:Motor Power, The Key to Choosing the Right Motor!〉

2. Precise Speed and Position Control

Gear motors reduce load inertia during deceleration, stabilizing speed and facilitating control. This is critical for applications requiring smooth low-speed operation, accurate stops, or precise positioning—such as conveyor belts, CNC machines, and packaging equipment. Gear motors ensure reliable, precise motion for consistent production quality.3. Optimized Space and Maintenance Costs

The integrated design saves installation space and simplifies mechanical structures. The gearbox absorbs part of the impact load, protecting the motor and extending overall lifespan. This reduces maintenance frequency and downtime, keeping equipment operating efficiently for longer periods.Core Industries for Gear Motor Applications: 5 Key Sectors

Gear motors are widely applied in industries demanding high torque and precise motion control, including industrial automation, material handling, food, and packaging. Here are five core sectors:1. Industrial Automation Equipment

Gear motors drive conveyors, sorting robotic arms, and chip conveyor machines on automated lines, ensuring stability and efficiency. Accurate speed and torque control help increase productivity and reduce energy consumption.2. Logistics and Warehouse Systems

In large logistics centers and warehouses, gear motors power conveyors, sorting systems, AGVs, AMRs and shuttle systems. They provide sufficient torque and precise control for accurate load handling, stacking, and transportation, with durability to withstand long-term friction and frequent starts/stops.3. Food Packaging and Medical Equipment

In automatic filling and sealing machines, gear motors control container movement, liquid filling, and capping. High precision ensures consistent production, minimizes waste, and maintains quality. In surgical robots, they drive joints for accurate minimally invasive procedures. Gear motors in these applications often use stainless steel, meet hygiene standards, operate quietly, and ensure reliability in sensitive environments.4. Automotive Industry

Gear motors are widely used in automotive production lines for conveyors and robotic arms. They are increasingly applied in electrification trends, powering AGVs, AMRs, and electric vehicles as part of smart mobility solutions.5. Aerospace and Defense

Gear motors provide high reliability and durability in aerospace inspection equipment, precision control platforms, and military applications. They maintain stable output in extreme environments, supporting the stringent requirements for precision and safety. Applications include driving ultrasonic sensors, X-ray scanners, and stabilizing radar or antennas under harsh conditions.5 Key Criteria for Choosing the Right Gear Motor

- Load Characteristics and Torque Requirements: Calculate torque based on weight, friction, and inertia, considering startup torque to ensure stable operation.

- Reduction Ratio and Output Speed Matching: Choose a reduction ratio that balances speed and torque for optimal efficiency.

- Installation and Space Constraints: Consider flange or foot mounting and available space to select the appropriate installation method.

- Duty Cycle and Environmental Conditions: Account for continuous or intermittent operation and conditions like temperature, humidity, corrosion, explosion-proof, or IP ratings.

- Brand Reputation and Technical Support: Select reputable brands that provide reliable support for selection, installation, and maintenance.

Boost Equipment Performance with SESAME Gear Motors

Sesame Motor specializes in gear motors and planetary gearboxes, offering high torque, low backlash, and long service life, compatible with major servo motor brands. With in-house manufacturing and strict quality control, Sesame gear motors meet the demands of industrial automation, logistics, food and medical equipment, and aerospace, delivering reliable and efficient solutions.〈READ MORE:What are Planetary Gearboxes?〉