- HOME

- FAQ

- Motors, Gear Motors

- How to Replace the Gearhead?

How to Replace the Gearhead?

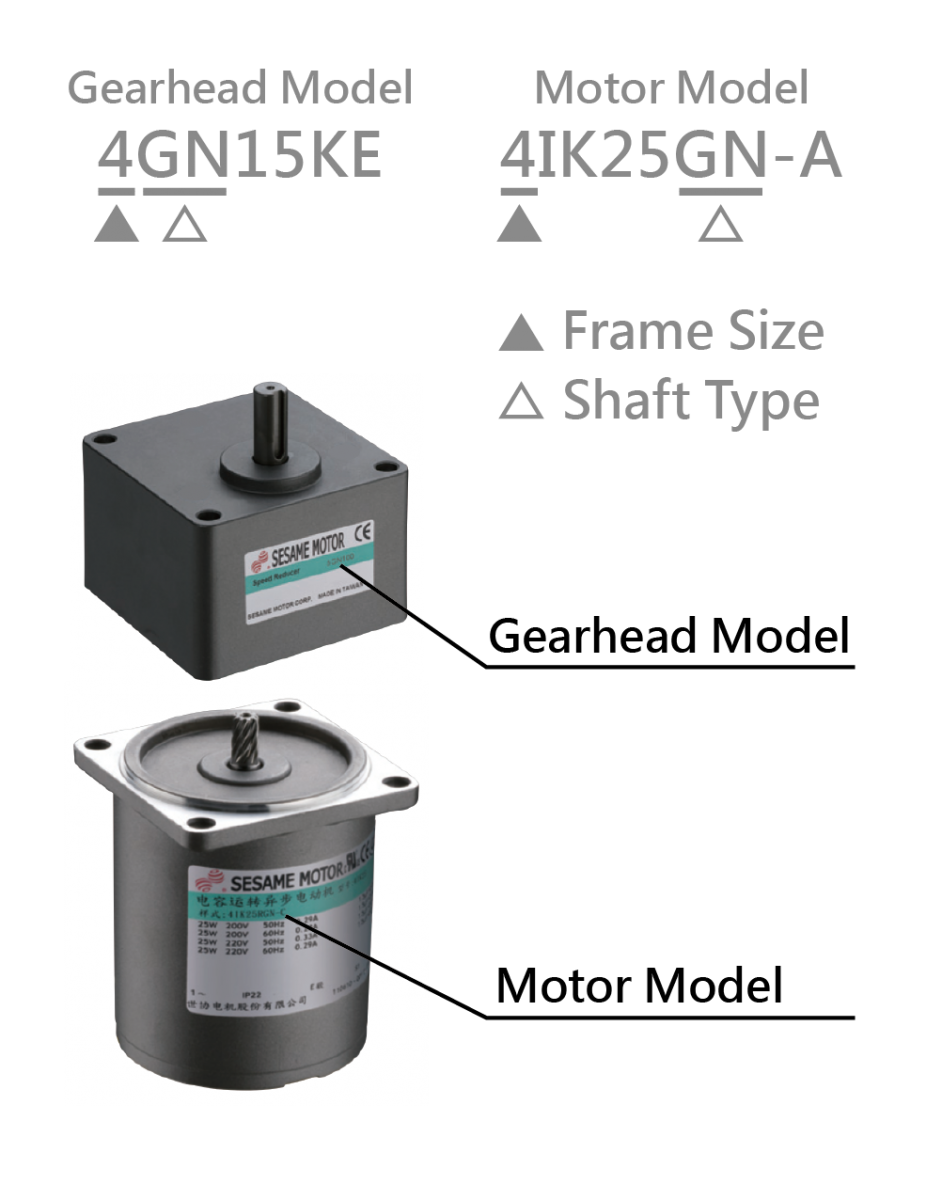

There are two types of output shaft of the AC standard motor: the round shaft and the pinion (geared) shaft, only the motor with pinion shaft can be assembled with gearhead (speed reducer). Depending on the model of the motor and the gearhead, the combination can be done when the model of the "frame size" and the "shaft type" are the same. Therefore, check the model of motor and gearhead before ordering and installing. If motor and gearhead do not mesh smoothly, tune the gearhead slightly left and right while assembling.

There are two types of output shaft of the AC standard motor: the round shaft and the pinion (geared) shaft, only the motor with pinion shaft can be assembled with gearhead (speed reducer). Depending on the model of the motor and the gearhead, the combination can be done when the model of the "frame size" and the "shaft type" are the same. Therefore, check the model of motor and gearhead before ordering and installing. If motor and gearhead do not mesh smoothly, tune the gearhead slightly left and right while assembling.

Do not force to combine the motor and the gearhead deliberately when assembling to avoid damages on the motor output shaft or the gear of the gearhead. Avoid foreign objects such as metal fragments fall into the gearhead, which may cause abnormal sound during operation or shorten the service life. After confirming that there is no gap between the motor and the gearhead, use hexagon socket screws to tighten and fix them up according to the torque in the table below.

| Models & Dimensions | Screw | Tighten Torque N.m |

||

| Motor | Gearhead | mm | ||

| 2IK | 2GN | 60 | M4 | 2.0 |

| 3IK | 3GN | 70 | M5 | 2.5 |

| 4IK | 4GN | 80 | M5 | 2.5 |

| 5IK | 5GN, 5GX | 90 | M6 | 3.0 |

Depend on the reduction ratio, the gearhead output shaft may be rotate the same or opposite to the motor shaft. Please pay attention to the rotation direction when changing the gearhead with different reduction ratio. (Please refer to the table below)

| Ratio | 3 | 3.6 | 5 | 6 | 7.5 | 9 | 12.5 | 15 | 18 | 25 | 30 | 36 | 50 | 60 | 75 | 90 | 100 | 120 | 150 | 180 | 200 |

| GN | same as motor | opposite of motor | same as motor | ||||||||||||||||||

| GX | same as motor | opposite of motor | same as motor | opposite of motor | |||||||||||||||||