What Are Planetary Gearboxes?

Gear reducers, also called gearboxes, derived from ancient metalworking process are foundation of many current innovations and techniques. Planetary gearbox is a type of speed reducers that were launched 30 years ago. At the beginning, planetary gearboxes have only appeared in high-end devices in Europe and America, then have gradually entered the field of automation. Now they are widely used in robotics, electric vehicles, 3D printing equipment, machine tools, semiconductor equipment, packaging, medical, food and beverage, aerospace and other industries, being a important power transmission component. A combination of servo motor and planetary gearbox is part of the standard configuration now. What are the benefits and applications of using planetary gearboxes? This article will let you know more about planetary gearboxes.

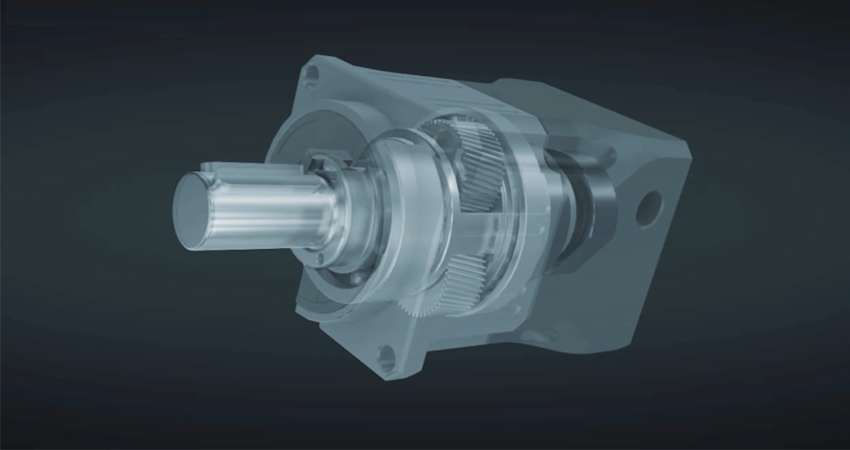

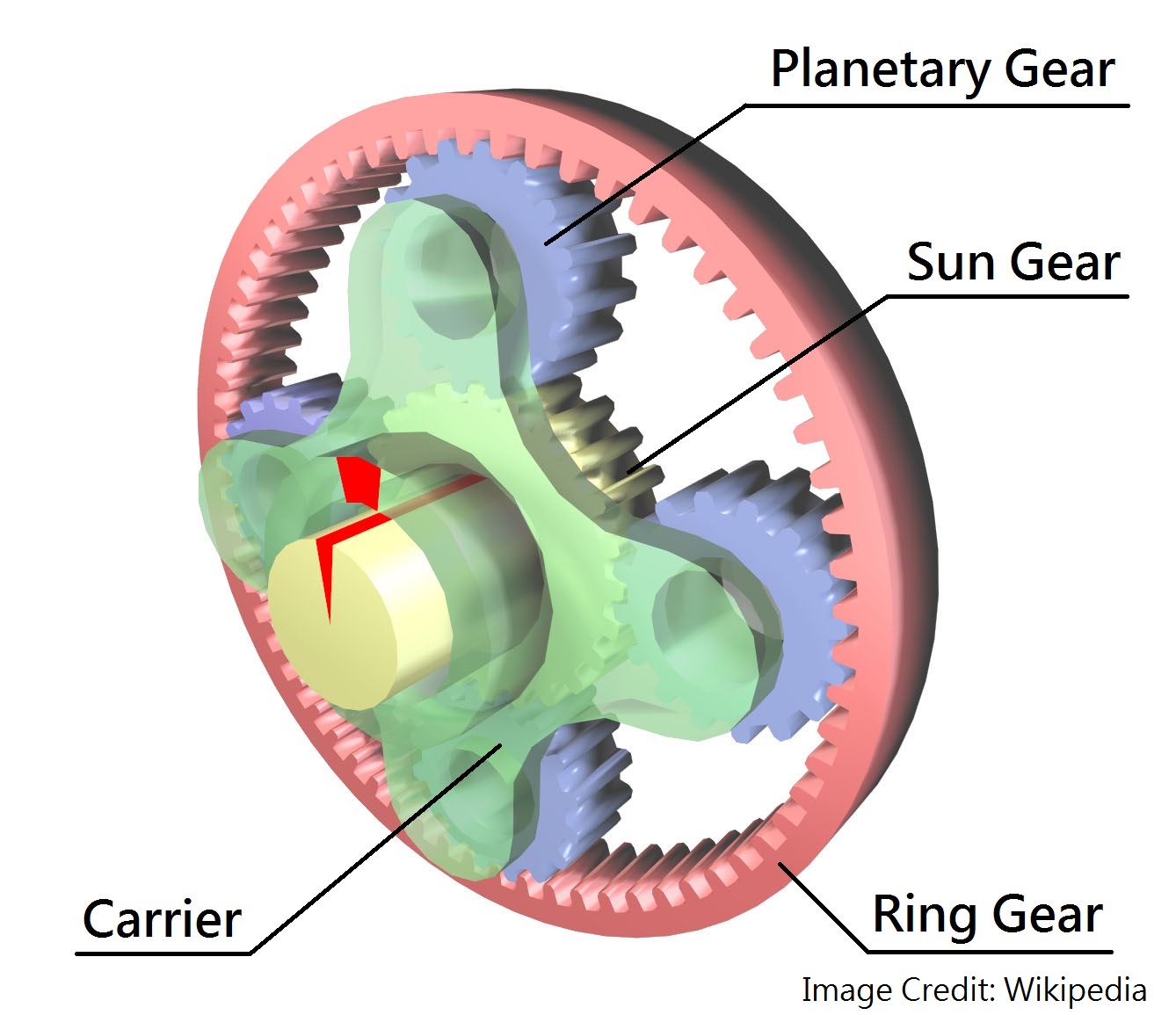

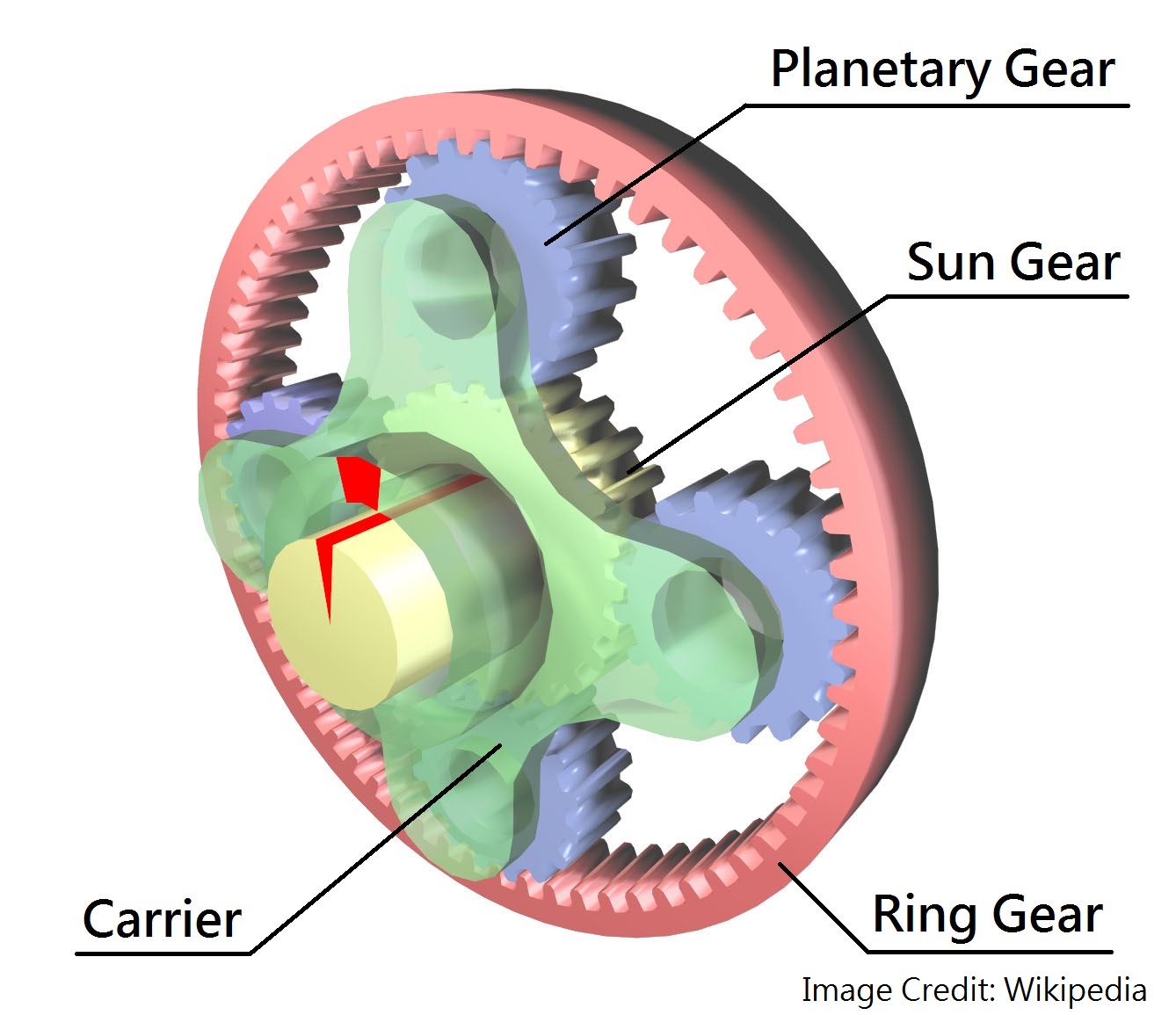

The internal structure of the planetary gearbox is an epicyclic gear train (also known as a planetary gear set) mainly constructed of four major parts: a sun gear, planetary gears, a ring gear and a planetary arm carrier. In this gear train, the ring gear is fixed while the sun gear (input shaft) driven by the motor is located in the center. The sun gear is driven and moves the planetary gears which are fixed on the planetary arm carrier. Every planetary gear rotates on its own axis while revolves around the sun gear. The planetary arm carrier is the output shaft of the gearbox that transmits the power of the motor when planetary gears rotate and orbit. The operation of such gear set looks similar to our planetary solar system and that is how it is named, a planetary gearbox.

The input shaft (sun gear) and output shaft (planetary arm carrier) are parallel configured. The output shafts are available with some options like key shaft, smooth shaft or spline shaft, on which belt pulleys, gears and sprockets, etc. can be installed and mounted to machinery.

The mounting flange of a planetary gearbox is designed according to ISO9409 specification. The flange type planetary gearboxes can be combined with various pinions and pulleys that provide high torque output in gears and racks applications.

The mounting of the servo motor is rotated 90° by a right angle housing, which saves space and makes the overall design of the equipment more compact.

<READ MORE: What are speed reducers? How do they work?>

What is a planetary gearbox?

The internal structure of the planetary gearbox is an epicyclic gear train (also known as a planetary gear set) mainly constructed of four major parts: a sun gear, planetary gears, a ring gear and a planetary arm carrier. In this gear train, the ring gear is fixed while the sun gear (input shaft) driven by the motor is located in the center. The sun gear is driven and moves the planetary gears which are fixed on the planetary arm carrier. Every planetary gear rotates on its own axis while revolves around the sun gear. The planetary arm carrier is the output shaft of the gearbox that transmits the power of the motor when planetary gears rotate and orbit. The operation of such gear set looks similar to our planetary solar system and that is how it is named, a planetary gearbox.

Types of planetary gearboxes

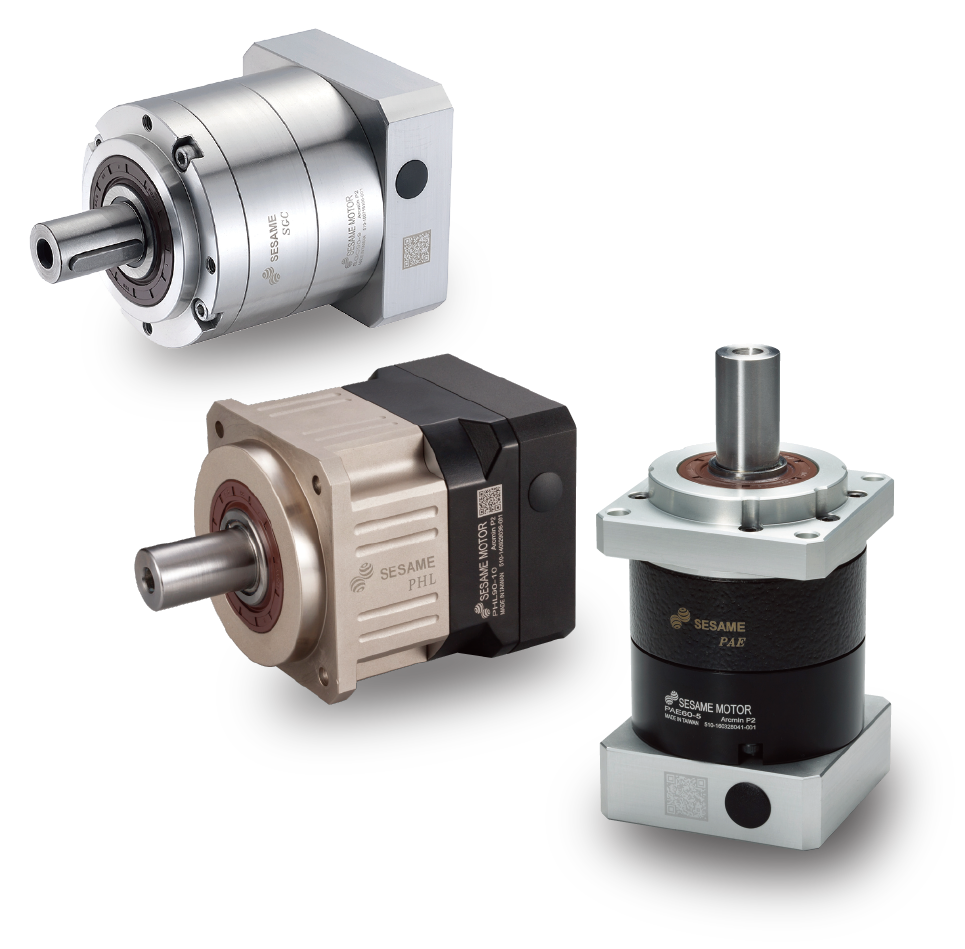

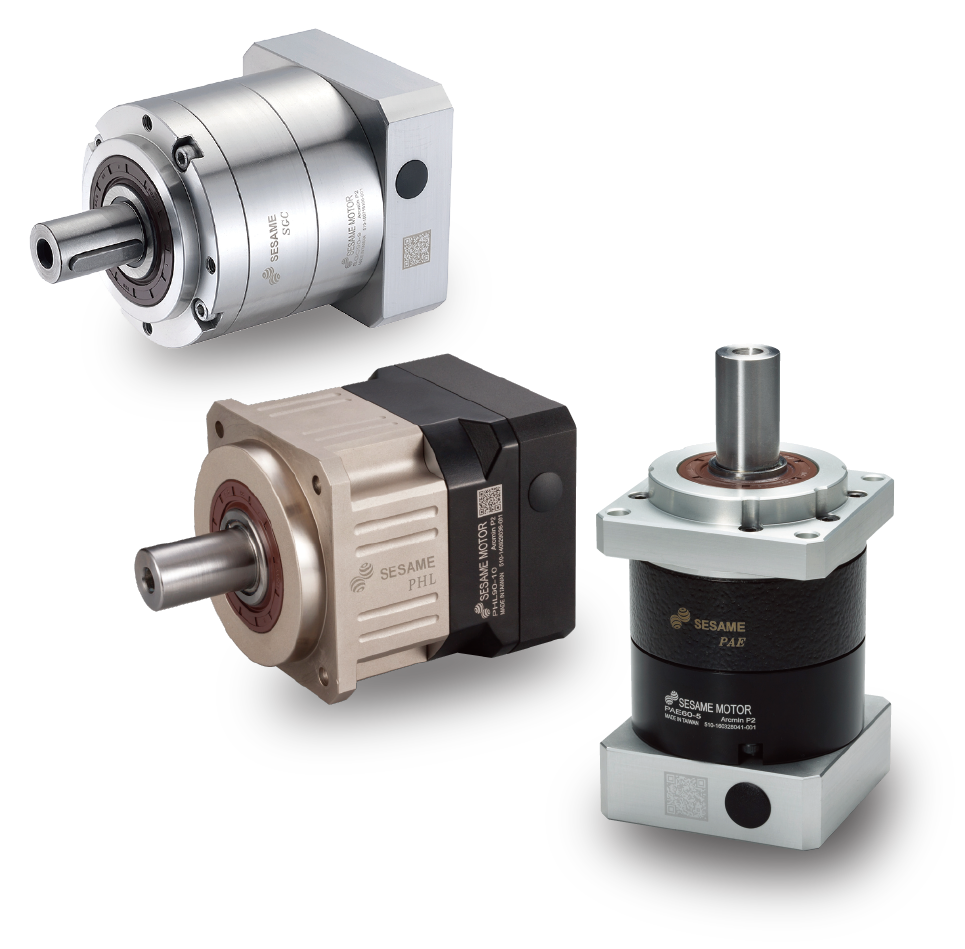

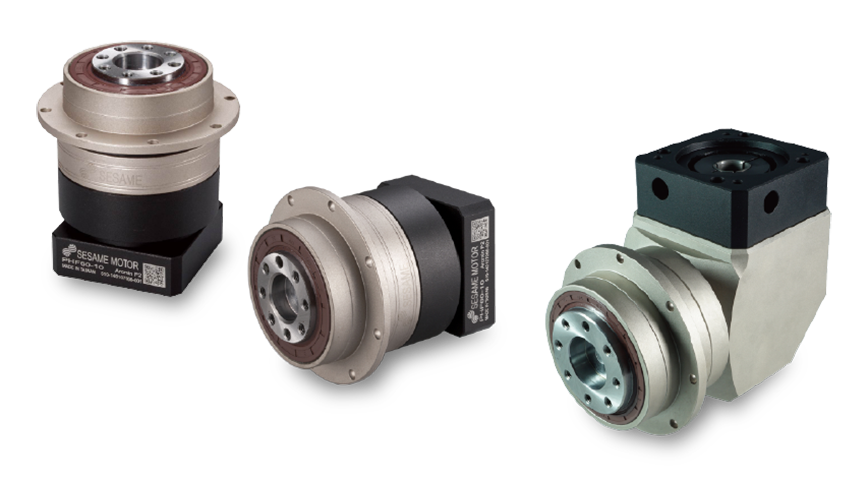

After years of development, there are the following types of planetary gearboxes:Output shaft type

The input shaft (sun gear) and output shaft (planetary arm carrier) are parallel configured. The output shafts are available with some options like key shaft, smooth shaft or spline shaft, on which belt pulleys, gears and sprockets, etc. can be installed and mounted to machinery.

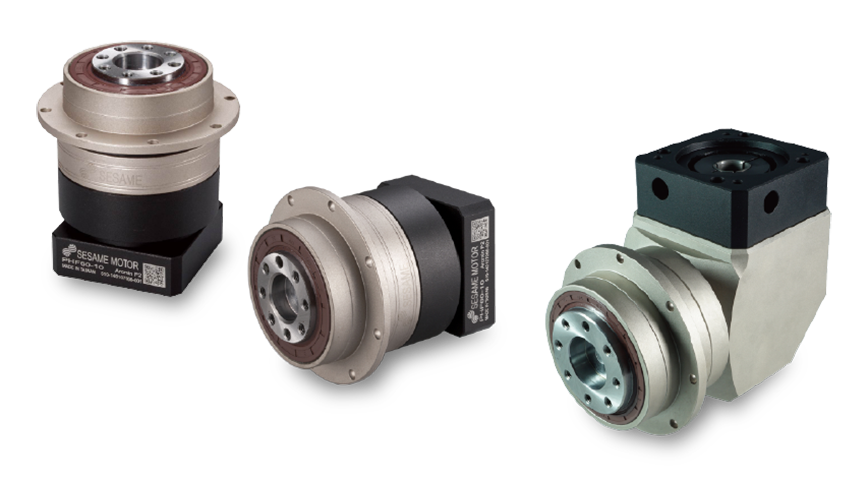

Flange type

The mounting flange of a planetary gearbox is designed according to ISO9409 specification. The flange type planetary gearboxes can be combined with various pinions and pulleys that provide high torque output in gears and racks applications.

Right angle type

The mounting of the servo motor is rotated 90° by a right angle housing, which saves space and makes the overall design of the equipment more compact.

Customized models

Sesame Motor has strong and flexible manufacturing capacity, which means that even the products that are not in the catalog can be produced according to the customer's requirement.Advantages of using planetary gearboxes

- High torque density

The planetary gear reducers can withstand higher torque than other types of speed reducers under the same volume. - Wide range of reduction ratio

Wide range of ratio options are available due to combination of two or more housing stages and matching of several planetary gears. - Economy

The required torque is offered by a planetary gearbox plus a lower power servo motor or stepper motor, to increase output torque and reduce the overall cost of configuration. - High precision

The backlash is up to 1 arcmin due to precision machined and surface-treated gears and housing. - Low noise

The lowest operation noise is 55 decibels only. - High efficiency

Low energy losses inside the gearbox ensures a high proportion and efficiency of the power transmission.

Where are planetary gearboxes usually used?

Due to the features and advantages of planetary gearboxes, they are often used when space and weight are limited, but high reduction ratio and high output torque are needed. Planetary gear reducers are not only used in industrial fields, they can be find in civilian products. Industrial applications include robotics, electric vehicles, automatic transmissions, machine tools, packaging, food and beverage machinery, medical equipment and automation area. Planetary speed reducers can be find in daily use products such as bicycle wheel hub gearbox and electric scooter drive train.<READ MORE: What are speed reducers? How do they work?>